METFIBER ECO WALL HF

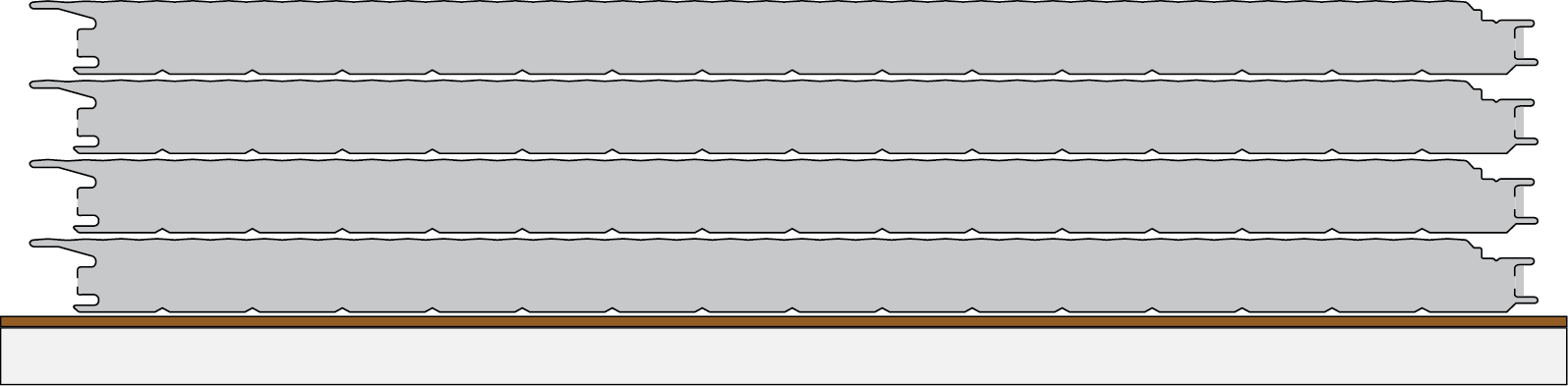

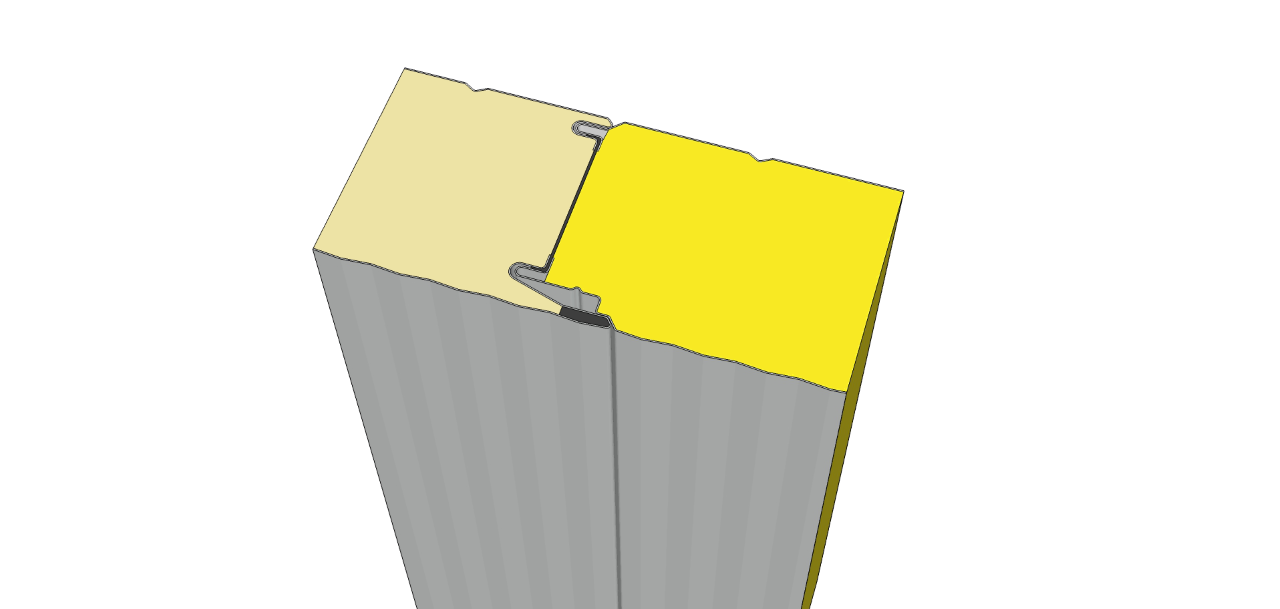

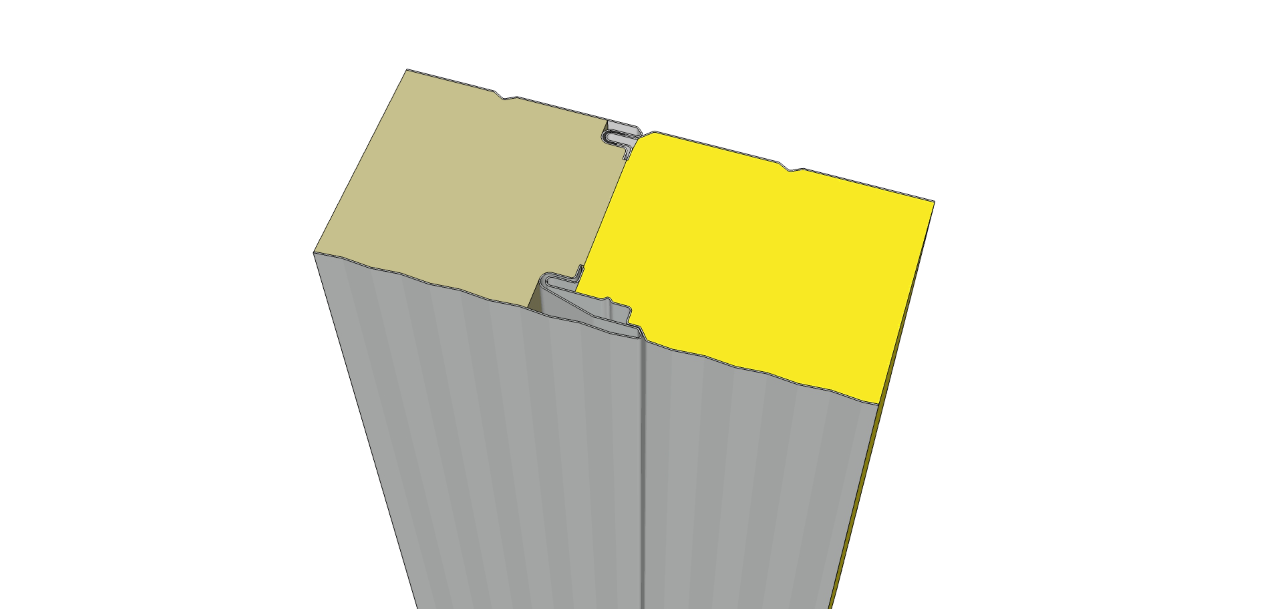

The Metfiber® Eco HF Wall panel with glass wool core and joint-geometry for hidden fixing fulfils all the requirements for non-combustible building materials and is excellently suited for both vertical and horizontal installation. The glass wool used in this product consists of 80% recycled material, thus contributing significantly to the saving of natural resources and making the product an ecological building material.

The deadweight of the panel is distinctly lower than that of conventional sandwich panels with rock wool insulation core, hence enabling an easier, faster installation and cost reduction, especially for longer panels.

For buildings exposed to high wind-suction, a horizontal single-span installation is recommended, so possibly needed visible fixing-screws may be covered by pilaster profiles.

Due to the large number of combinations with other panels from our portfolio with polyurethane or rock wool insulation core, it is possible to reach fire-safety, acoustic and thermal requirements at once without any visual impact.

Please have a look at our detailed technical manual for further information.

weiterlesen >>| Element name | Element thickness | Outer shell | Inner cover shell | weight | Thermal resistance | Heat transfer coefficient (Ψ - Joint factor) | |

|---|---|---|---|---|---|---|---|

| s | tN | tN | kg / m² | R | U without Ψ | U with Ψ | |

| mm | mm | mm | kg / m² | m² K / W | W / m² K | W / m² K | |

| METFIBER ECO HF WALL | 100 | 0,60 | 0,60 | 17,2 | 2,54 | 0,370 | 0,400 |

| 120 | 0,60 | 0,60 | 18,5 | 3,05 | 0,310 | 0,330 | |

| 150 | 0,60 | 0,60 | 20,1 | 3,82 | 0,250 | 0,270 | |

| 200 | 0,60 | 0,60 | 23,7 | 5,10 | 0,190 | 0,200 | |

| * no approval / on request | 240* | 0,60 | 0,60 | 26,3 | 5,42 | 0,162 | 0,164 |

Reachtion to Fire

Building material classified as A2-s1, d0 non-combustible according to DIN EN 13501-1

Thermal Conductivity

λ=0,039 W/m.K under the terms of DIN 4108 and DIN EN 13162

Sound Insulation

Rw ≥ 31 dB

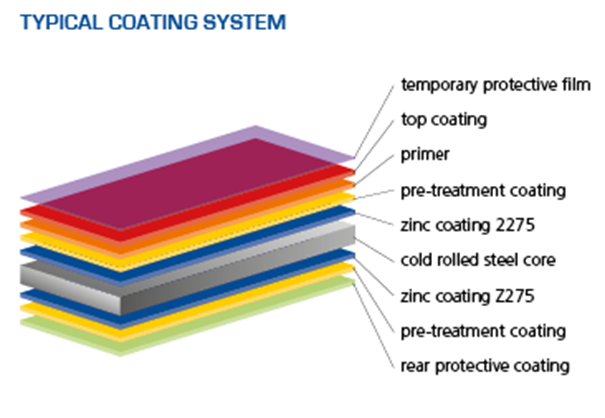

Corrosion Protection

- Standard version with external and internal steel sheet of 25 μm polyester

- External and internal steel sheet: category RC3 (under the terms of DIN EN 10169)

Standard lengths

> 2,00 m up to 25,00 m, greater lengths on request.

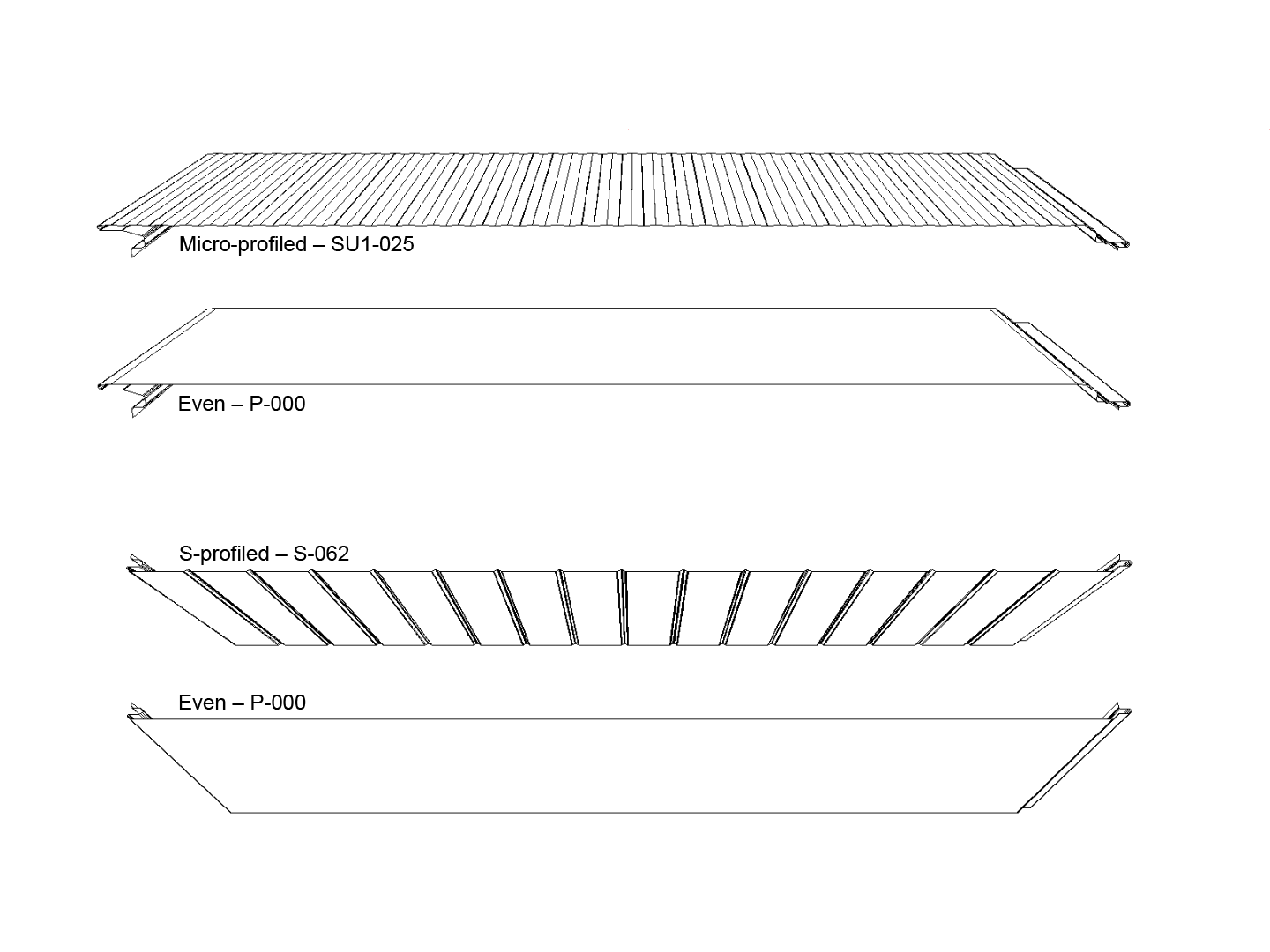

Types of profiles

External/internal sheet

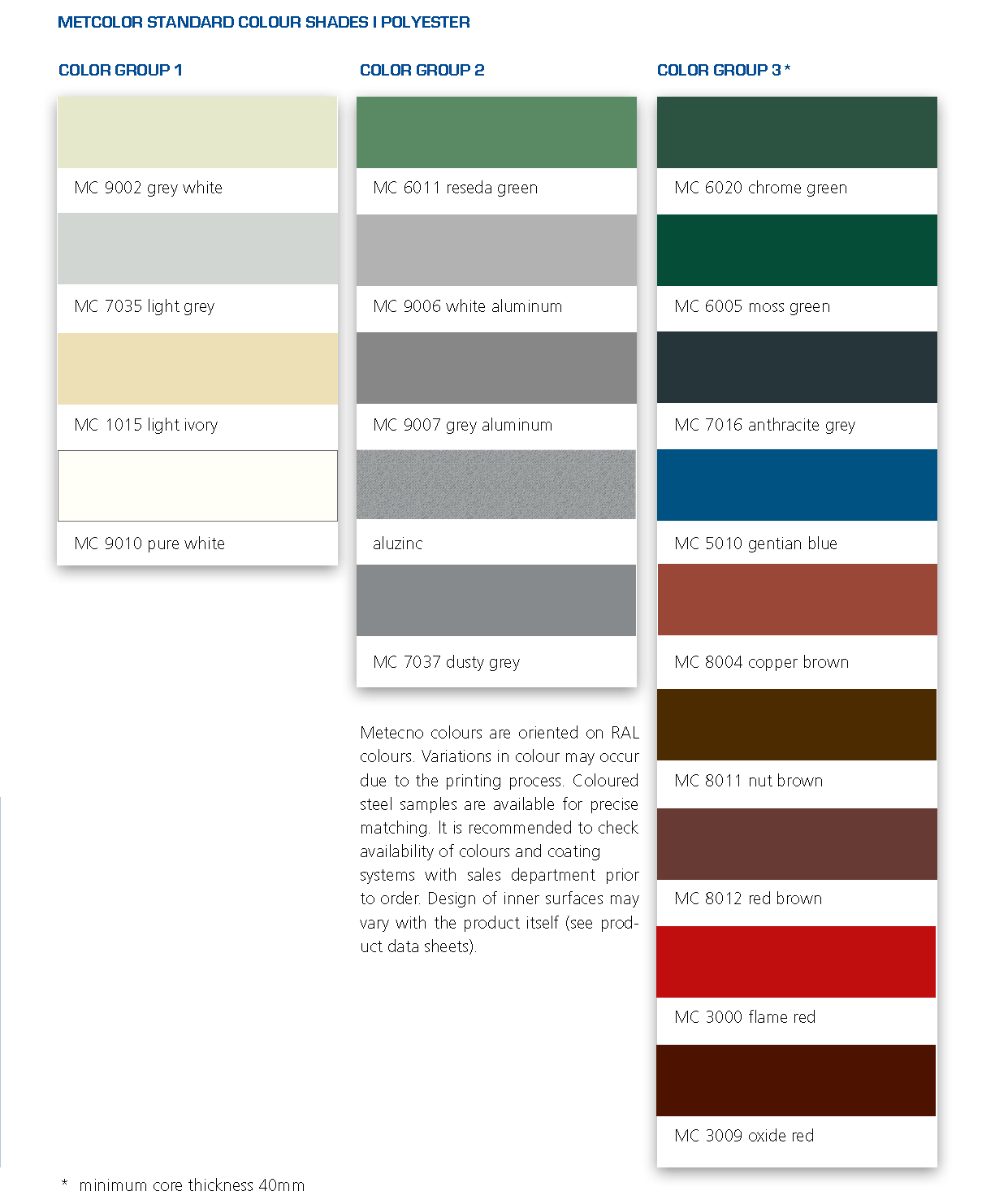

STANDARD COATING FOR EXTERNAL APPLICATION

25μm POLYESTER

Corrosivity category RC3 in accordance with DIN EN 10169:2010-2

UV resistance category RUV2 in accordance with DIN EN 10169:2010-2

Temperature exposure -20° to 80°C

The well-proven polyester-coating is a modern and costeffective coating system, adapting well to different colour finishes. Polyester-coatings show good corrosion- and weather resistance under normal conditions for industrial application within the Central European region, which makes it the most frequently used coating system.

STANDARD COATING FOR INTERNAL APPLICATION

15 μm DU-POLYESTER

Corrosivity category RC2 in accordance with DIN EN 10169:2010-2

Temperature exposure -20° to 80°C

The polyester-thin-coating (standard colour shade similar to MC 9002) is suitable for conventional industrial buildings for indoor application in rooms with normal room climate and normal relative humidity. The colour shade may not be uniform due to the coating thickness.

25 μm OR 35 μm PVDF (POLYVINYLIDENFLUORIDE) - On request

Corrosivity category RC3 (25 μm) or RC4 (35 μm) in accordance with DIN EN 10169:2010-2

UV resistance category RUV4 in accordance with DIN EN 10169:2010-2

Temperature exposure -20° to 110°C

This coating shows optimal resistance against UV-radiation and weather and has good ductility. lt is suited particularly well for high requirements on the colour finish and has been found to be excellent in regions with difficult climatic conditions (e.g., 5-15 km from the sea).

Our recommendation for outdoors (indoors)

50 μm POLYAMIDE MODIFIED POLYURETHANE (PUR-PA) - On request

Corrosivity category RC5 in accordance with DIN EN

10169:2010-2

UV resistance category RUV4 in accordance with DIN EN

10169:2010-2

Temperature exposure -20° to 80°C

By using polyamide this coating system reaches a high surface hardness. lts visibly grained structure is particularly resistant to abrasion and ensures efficient protection against mechanical damage. lt is also widely resistant to strain by animals such as poultry, making it ideally apt for agricultural application. The flexibility and excellent resistance to UV radiation make this coating also suitable for outdoor installation.

Please also have a look at our Guideline for the Selection of Coating Systems.

Thickness of steel sheets

External steel sheet 0,60 mm (optional: 0,75 mm)

Materials

Optional version

- Under the terms of the applicable EU Construction Products Regulation, production according to DIN EN 14509, CE label under the terms of the EG Conformity Certificate 0769-CPR-VAS-00420-1

- DIBt Approval for Use Z-10.49-613 as self-supporting sandwich panel under the terms of DIN EN14509

External sheets provided with removable protective foil, panel-packages wrapped with banded plastic foil to protect from soiling. Also, package weights of max. 2,5 t or 1,5 t are available on request.

Container shipment

On request, we provide container packaging apt for oversea shipping. The panels will be stored in containers of 20 feet (6,096 m) or 40 feet (12,192 m), including an unloading system for easy unloading of the packages at their destination.

Number of panels per package

Core thickness Number*

Way of Packaging

- SUPERWALL ML

- SUPERWALL HF

- Deutschland