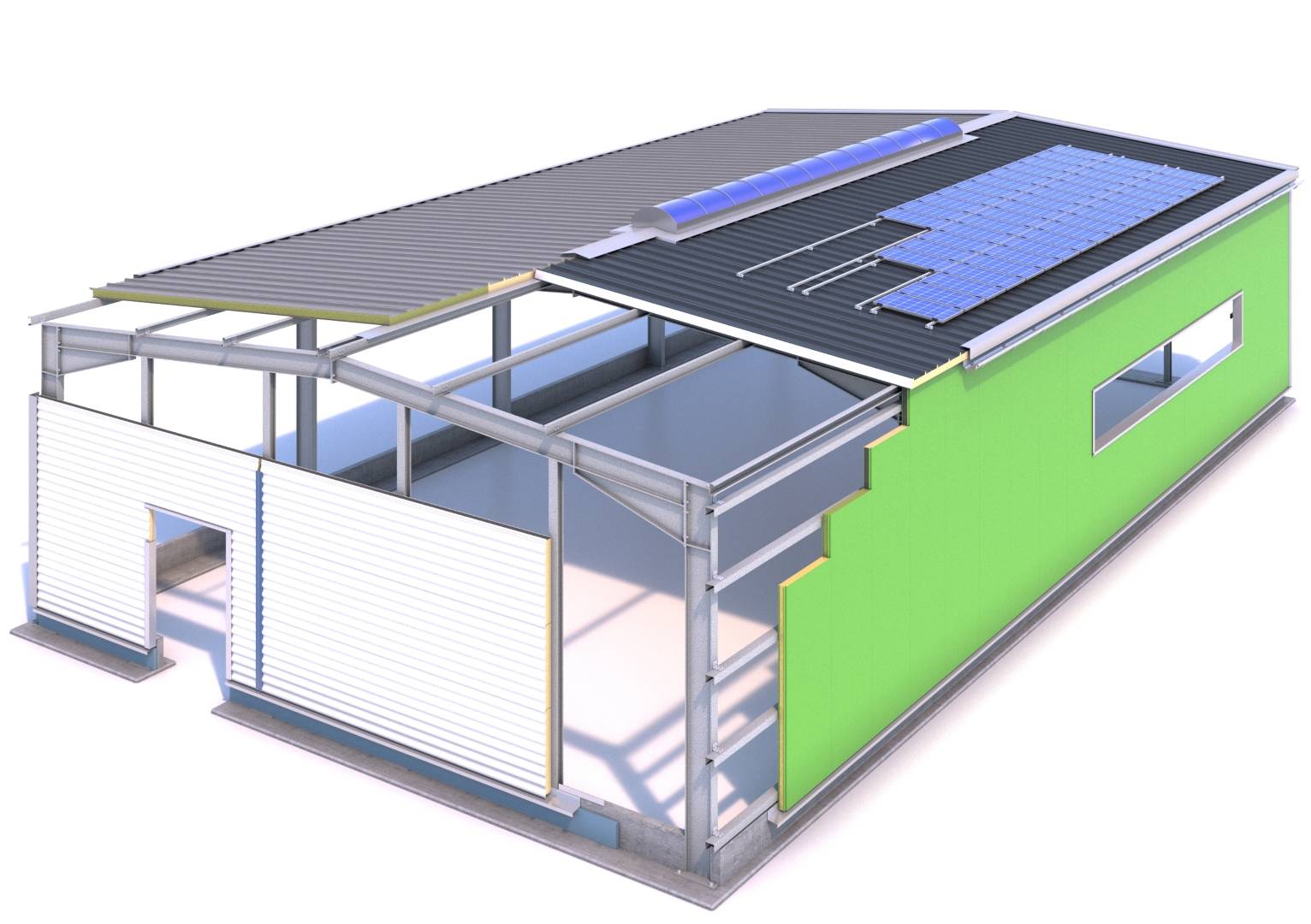

Product application

By simply clicking on the 3D-animation below you can find the right roof of wall-panel for your project. No profound knowledge about our wide product range of various profiles and insulation cores is required. In case of any questions regarding our product-portfolio or the specific application of the products shown our sales team is more than happy to help.

MetECKno corner

Discover our new design corners made of sandwich panels for the execution of your individual architectural ideas…

… with a maximum panel length of 8,000 mm!

… with a minimum web dimension of 200 mm!

… as horizontal or vertical corners!

… as outer corners as well as inner corners!

… with core thicknesses from 30 mm up to 200 mm!

… with an insulation core made of rock -/ glass wool or PUR/PIR foam!

In cooperation with On Spot Manufaktur Leipzig.

zur Produktseite

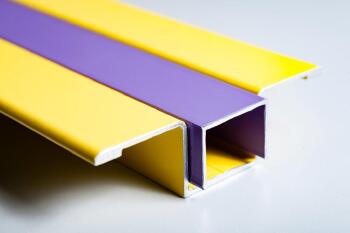

Pilaster strips

Our aluminium pilaster strips are easy to install and available in two versions (110 and 160 mm), each with two different cover strips (high and low). These aluminium profiles are made of EN AW-6060T66 EN 755-9-material with available lengths up to 6.000 mm. The pilaster strips are powder-coated and available in any RAL-colour finish.

Your benefits at a glance:

+ light-weight construction

+ no displacement after installation due to tight fit

+ rounded edges for uniform joint appearance

+ installation aid to prevent damage

zur Produktseite

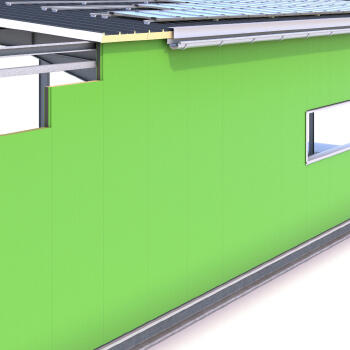

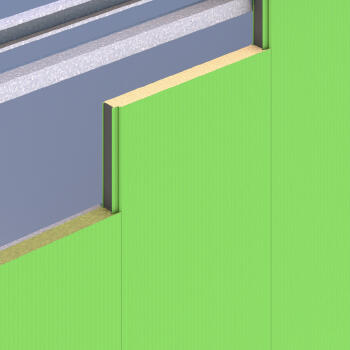

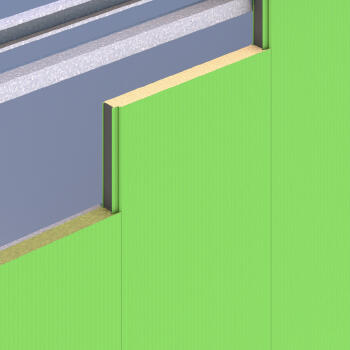

Sandwich panels wall

You can find the most diverse combinations for the respective product under"Combinability with other products".

zur Produktseite

The low thermal conductivity of the PIR rigid foam core makes this panel especially apt for application as thermal insulation. At the same time, it provides a weather-resistant outer shell in only one working step. Hence, we can provide great thermal insulation values with relatively thin sandwich panels with PIR core.

Due to their high level of prefabrication, buildings with sandwich panels can be constructed within a relatively short time, thus reducing installation costs significantly. The low deadweight contributes to shorter delivery times and lower transportation costs as well as it lowers expenditure for support constructions.

zur Produktseite

For reasons of fire and sound protection, sandwich panels with a non-combustible core of rock wool are very often requested. The insulation core consists of rock wool fibres, spun from liquefied rock (with a melting point over 1000°C). Installed with the correct details, sandwich panels of the HIPERTEC-product range can provide fire resistance for wall and roof systems. Especially for extensive and multi-storey industrial buildings, non-combustible materials have become absolutely essential. These products are ideal for applications in sound proofing and where non-combustible material is needed, especially in case additional fire resistance for wall and roof systems is requested.

zur Produktseite

The insulation core made of glass wool meets the requirements of a non-combustible building material.

Especially when working with greater core thicknesses, one notices the much better U-value of this product (caused by the lower lambda value of 0,039 W/m²K) in comparison to conventional panels with a rock wool core.

Because of the low bulk density of the glass wool core, the sandwich panels of the Metfiber product range have less deadweight than conventional sandwich panels. This makes their assembly easier and reduces costs, especially when long panels are concerned. The glass wool consists of 80% recyclable material, saving natural resources. The optimal fields of application for these products are soundproofing, thermal insulation and when non-combustible building material is needed.

zur Produktseite

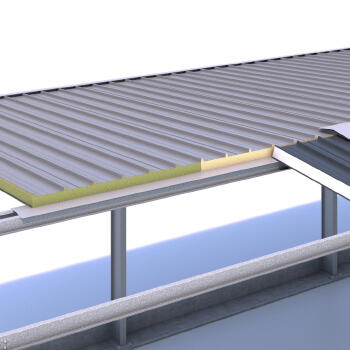

Sandwich panels roof

You can find the most diverse combinations for the respective product under"Combinability with other products".

zur Produktseite

The low thermal conductivity of the PIR rigid foam core makes this panel especially apt for application as thermal insulation. At the same time, it provides a weather-resistant outer shell in only one working step. Hence, we can provide great thermal insulation values with relatively thin sandwich panels with PIR core.

Due to their high level of prefabrication, buildings with sandwich panels can be constructed within a relatively short time, thus reducing installation costs significantly. The low deadweight contributes to shorter delivery times and lower transportation costs as well as it lowers expenditure for support constructions.

zur Produktseite

For reasons of fire and sound protection, sandwich panels with non-combustible core of rock wool are requested very often. The insulation core consists of rock wool fibres spun from liquefied rock (with a melting point over 1000°C). Installed with the correct details, sandwich panels of the HIPERTEC-product range can provide fire resistance for wall and roof systems. Especially for extensive and multi-storey industrial buildings, non-combustible materials have become absolutely essential. These products are ideal for applications in sound proofing and where non-combustible material is needed, especially in case additional fire resistance for wall and roof systems is requested.

zur Produktseite

H-Wall 8P

This sandwich panel with a sinus-corrugated external sheet and hidden fixing is a great esthetical option for modern facades by giving them a lively touch with its original wave design. The highly heat-insulating CFC-and HCFC-free polyurethane rigid foam core is suited best for today's requirements for thermal insulation and moisture protection. A non-displaceable sealing strip foamed into the longitudinal joint procures resistance to driving rain and wind. Together with the organic coating of the steel sheets, this ensures efficient protection against all kinds of weather.

Optionally, the internal sheet can be ordered stucco-embossed to reduce possible mirror effects on the surface. For an advanced application, additional coating systems are available.

Please have a look at our detailed technical manual for further information.

zur Produktseite

Flashings

Made of galvanized, coated steel.

Material thickness 0,75 mm; maximum lengths up to 6.000 mm.

Side A: 25 μm polyester coating with protective foil

Side B: RSL protective coating

Available in colours matching the cover sheets of the panels.

Production possible on the basis of profile drawings sent by customer or with item number according to our flashings-catalogue. Special designs on request.

DESIGN DETAILS

Our planning folder contains detailed proposals and application solutions in PDF-and DWG-format. It also contains text templates for the quick preparation of tenders with our sandwich elements and flashings.

zur Produktseite

Photovoltaics

With the extended general approval Z-10.4-583 for our panels with PUR/PIR-foam core the following applications are possible with immediate effect*:

Installation of the new/modified solar fasteners on G4-roof panels with continuous core thickness ≥ 40 mm as certified all-in-one system with general approval. The addition of the trapezoidal clamp “Clamp Fit” as well as geometric changes of the already existing clamp “Single Fix-V” have been taken into account.

Advantages of our combined system:

Approved according building laws

Non-penetrative application, no thermal bridges

All-in-one system – screws included

Almost non-cutting installation

Independent of support construction

zur Produktseite